In a groundbreaking move towards a sustainable aviation industry, AIRBUS has set its sights on introducing a hydrogen-powered medium-haul aircraft with zero CO2 emissions by 2035. This ambitious project is part of AIRBUS’ broader strategy to combat climate change and reduce the aviation sector’s carbon footprint. Fuelled by the heightened focus on decarbonisation and increasing global air passenger traffic, hydrogen propulsion has the standout advantages to be near-zero emissions, as hydrogen combustion or fuel-cell operation produces only water vapor.

AIRBUS’ innovative zero-emission propulsion technology includes a hydrogen-powered nacelle with a complete electrical system composed of electric motors, fuel cell modules, battery, support systems and a cryogenic tank of liquid hydrogen at -253°C. Nonetheless, the storage of hydrogen in aircraft presents significant challenges across various dimensions, including the weight and volume of hydrogen storage systems, energy efficiency, the longevity of hydrogen storage, refueling speed, associated costs, and adherence to industry standards.

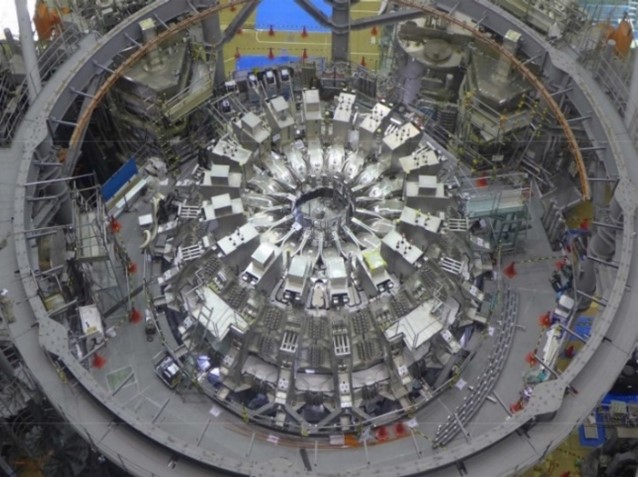

Quench modelling code and lessons learned from WEST and JT-60SA fusion experiments help considering potential accident risks in liquid hydrogen tanks

The liquid hydrogen storage system features an insulating vacuum encased within a cryostat, susceptible to two major incidents: air ingress from the external environment, which can lead to solidification and the formation of obstructions (such as water or nitrogen), and hydrogen leakage from within the tank in the event of structural damage. Any compromise of the insulation vacuum results in thermal losses affecting the tank.

AIRBUS signed a contract in 2021 with CEA to tackle this challenge and study defect rates/modes of liquid hydrogen storage components, safety modelling and assessment of potential accidents with heat ingress on cryogenic tanks. CEA leverages on its quench modelling code STREAM (Superconductor Thermohydraulic and Resistive Electrical Analytical Model) which was successfully developed for the analysis of WEST TFC09 Quench[1] and now used to partly characterise accidental heat fluxes on LH2 tanks with a particular expertise in preliminary estimates LOss of VAcuum (LOVA) Incident (in gas or supercritical fluid).

[1] Quench is an irreversible transition from superconducting state to normal resistive state. If not quickly detected, it may lead to possible permanent damage of the magnet. The 19th of December 2017, at the end of plasma run #52205, a quench of TFC09 was detected, first on a thermohydraulical signal (helium liquid level), and triggered the current Fast Safety Discharge (FSD).

In addition to the STREAM code, feedback and lessons learned by fusion scientists during tokamak experiments, including the quench incident in WEST and the loss of vacuum incident in JT-60SA, provided invaluable insight to the project in terms of risk analysis and insulation strategy.

“Following the incident (17/05/2021) on the 20 000 Liter helium tank (leakage of the nitrogen “screen” guard into the isolation void), the corresponding heat loss calculations in normal and degraded conditions allowed CEA to recommend to Airbus an optimal number of Multi Layer Insulation (MLI) of the Hydrogen tank. With superconducting coils thermally insulated by the cryostat vacuum, JT-60 SA also faced an incident on the EF1 coil (09/03/2021) characterised by a helium leak and an arc on the external electrical connection that generated a rapid pressure rise in the cryostat. Hence the importance for Airbus to consider potential accident risks and mitigation methods at a very early stage in liquid hydrogen tanks design, thanks to lessons learned by CEA in fusion”.

Sylvie NICOLLET, Research Engineer, Commissariat à l’énergie atomique et aux énergies alternatives (CEA-IRFM)

An inspiring synergy between fusion and aviation with strong benefits for both parties

In a bid to address the dire socio-economic impacts of aviation pollution, the aviation industry is on the cusp of a revolutionary change. While current aircraft contribute a significant 12% of global carbon emissions in the transportation sector, AIRBUS is constantly looking to harness innovative technologies to help achieve its goal of bringing zero-emissions aircraft to market by 2035.

Hydrogen propulsion, though not without its technological challenges, has the potential to revolutionise society’s approach to decarbonisation thanks to its ability to provide a completely CO2-free energy source, offering a glimmer of hope in the fight against climate change. The contribution of CEA scientists on cryogenic tanks brings AIRBUS closer to make hydrogen-powered flight a reality.

For the CEA, this collaboration represents an extraordinary opportunity to leverage its existing expertise related to the WEST and JT-60SA tokamaks and to take on new research and development challenges. Furthermore, this initiative aligns perfectly with the objectives of the France 2030 investment plan[1], promising access to vital funding that can drive innovation and propel the nation towards a greener, more sustainable future.

[1] France 2030 – The Future-Facing Investment Plan Accelerating French Research and Industry https://www.myresearchconnect.com/france-2030-the-future-facing-investment-plan-accelerating-french-research-and-industry/

Thanks to the effort invested and the result achieved in further using a fusion innovation in a new application outside the ITER project, CEA received the Technology Transfer Award 2023.

“Europe’s contribution to fusion projects is offering companies and laboratories the opportunity to increase their competitiveness and to transfer the know-how of fusion applications to non-fusion markets.”

Carmen Casteras, Intellectual Property and Technology Transfer Officer, Fusion for Energy (F4E).