How fusion brings concrete benefits to the European industry

Discover our success stories of spin-offs, increased competitiveness, and innovation

Clean Sky Ahead: Safer hydrogen-powered aircrafts thanks to lessons learned from fusion experiments

The Fusion Technology Transfer Award 2023 was granted to CEA for its project leveraging on its quench modelling code STREAM and lessons learned during WEST quench incident and JT-60SA loss of vacuum incident to develop safer hydrogen tanks and support AIRBUS to bring zero-emissions aircraft to market by 2035. A 10 000 EUR prize has been handed to this initiative which highlights the benefits of fusion know-how to safety modelling and cryogenics system. ‘Fusion projects are increasing European competitiveness in cutting-edge technologies’ Susana Clement, F4E Head of the Broader Approach Programme and Delivery Department (JT-60SA, IFERC, and IFMIF Projects).

HEF Group tackles challenges in the tire industry thanks to the capabilities of its fusion related vacuum deposition equipment.

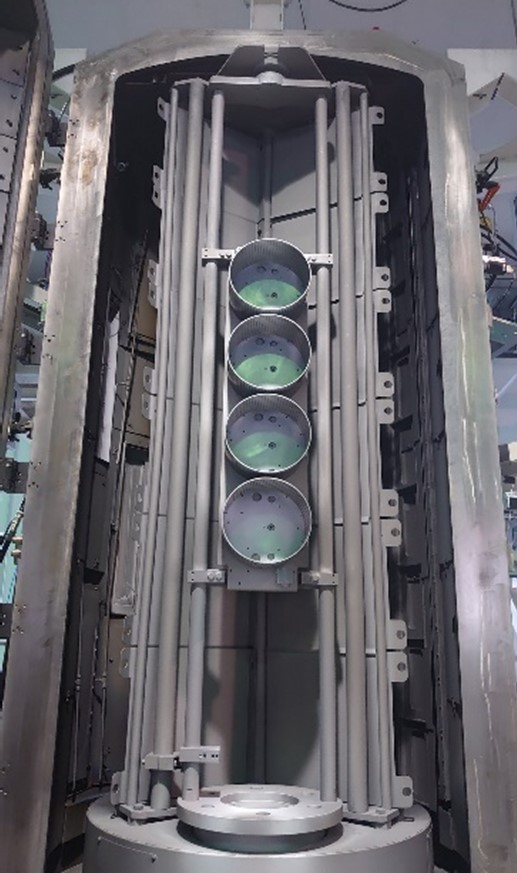

Coatings for Tokamak-type fusion reactors such as ITER, and associated experiments such as SPIDER, MITICA, WEST or ELISE require specific skills and equipment’s. In this context, the French group HEF/IREIS has developed a new equipment called TSD 2800 R, that combines magnetron sputtering, PECVD, and arc deposition sources dedicated to thin film solution of Molybdenum deposit.

MAGIC Lancer II robotic manipulator leverages on ITER-related radiation resistant microchips for easy and reliable nuclear power plant inspection

INETEC – Institute for Nuclear Technology is a well-known international engineering company located in Croatia and specialised in robotic systems, instruments, probes and software for nuclear power plant examination, inspection, repair services and R&D studies. In October 2021, INETEC started a project in the scope of the EU-funded RIMA project (Robot recruitment for inspection and maintenance operations) to develop a fully digital and more sustainable radiation-resistant robotic manipulator “LANCER II” to support nuclear inspections at the reactor vessel. The research included two main parts: the first was about the development of the manipulator that represents a new generation of mobile and light robotic systems developed at INETEC to perform the complete examination of reactor pressure vessel (RPV) shell- UT, ET, VT on both pressurized water (PWR) and VVER (water-water energetic) reactor types.

When a 3D machine vision system used in ITER for remote handling helps minimise blind spots in mobile machinery : Technology Transfer Award 2022

University of Tampere has developed, in collaboration with F4E and VTT (Technical Research Center of Finland), an innovative 3D target tracking system designed for remote handling operations. A successful test was operated on a vehicle used to handle and stack shipping containers to tackle blind spots’ issues. In this pilot, the technology developed with F4E has been applied to calibrate a 3D camera system that allowed the operator to see what stood behind the container. The numerous applications in mobile machinery and the opportunity to build a sustainable business model have given the incentive to the University of Tampere and Olli Suominen to set up a spin-off company by the end of the year.

Housing inspection technology for ITER’s vacuum vessel parts accelerates component qualification in the steel industry

The ITER vacuum vessel is one of the key components of the machine, as it must provide a high-quality vacuum for the plasma to be produced and acts as a first safety containment barrier. Like for the other components of ITER, drastic tolerances are required for these holes, and each of them must be precisely inspected and qualified.

To realize these compliance measurements rapidly and with a high accuracy, the Italian SME AXIST developed in collaboration with F4E an innovative measuring tool able to automatically inspect holes (diameter, axis perpendicularity, thread step, angle and length). Building on this success, AXIST further used the knowledge acquired during the HIT project and developed a new inspection system for the steel industry.

When a fusion PhD helps further disseminating additive manufacturing in the automotive industry thanks to his research work on ITER first wall panel parts

During his PhD at Stockholm University, Yuan Zhong investigated with F4E the feasibility of additive manufacturing of tungsten as irradiation barrier and developed a full-scale prototype of first wall cooling panel using two additive manufacturing technologies (Laser powder bed fusion and Electron beam powder bed fusion). With his team, Yuan Zhong worked on parameter development for additive manufacturing (AM) of 316L powder, material verification and validation and finally the production.

From impurity diagnosis of fusion plasma to an in-line control system using multispectral vision

Wouter Vijvers, who worked at the Dutch Institute for Fundamental Energy Research (DIFFER) and the Swiss Plasma Center (SPC), developed a new imaging diagnostic known as MANTIS (Multispectral Advanced Narrowband Tokamak Imaging System) to analyse fusion plasma. Convinced of the market potential outside fusion, he decided to create the spin-off company Chromodynamics which is now involved in several projects for medical, high-speed Raman imaging spectroscopy, pharmaceutical and semiconductor applications.

Fusion remote handling innovation conducts tele-operation technology enhancement for robot companion services

Heemskerk Innovative Technology identified a major need in the healthcare sector and decided to transpose its remote handling knowledge to it. The remote handling system developed for the maintenance of ITER has yielded to a Remotely Operated SErvice Robot (ROSE) prototype providing home care support for elderly and non-autonomous people.

Welding ITER vacuum vessel components help Pro-beam signing contracts with Ariane Group and Solar Orbiter

In charge of the electron beam welding of five of the nine sectors to the ITER vacuum vessel, pro-beam has upgraded its processes and built two K6000 giant electron beam (EB) welding machines. As it is unique in its size and complexity, the concept of the K6000 machine is being commercialized and has found further applications in aerospace industry.

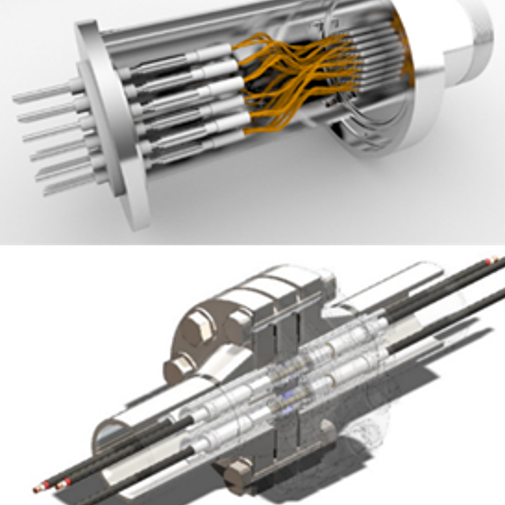

ITER electrical connectors open a new market for VAC-TRON in the Oil and Gas industries

An innovative Glass-to-Metal Sealing (GTMS) technology developed for ITER is now used to secure the energy supply for pumps and compressors in the gas industry.

ITER wires and cables generate new sales and jobs creation outside fusion for Axon’Cable

A new process developed to use thermoplastic polymide (TPI) for wire and cable insulation in fusion is now shared by more than 30 customers worldwide and boosts the cables revenues.

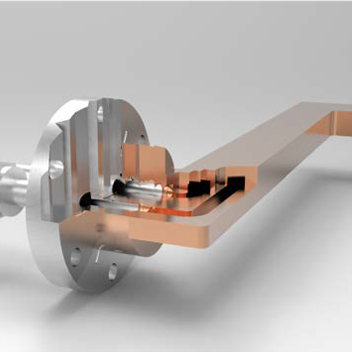

Fusion manufacturing know-how cools down space thrust chambers and particle accelerators

Based on copper deposition, a new industrial method has been implemented by CECOM with F4E during the Spider project to manufacture the grids for the Beam Source. This technology is mature and is now tested and implemented to tackle new challenges in non-fusion projects such as components of space thrust chambers or particles accelerators.

Bruker Biospin rocketed to world leader position in NMR market

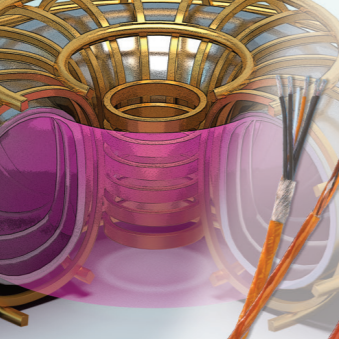

A new superconducting strand composed of niobium-tin now used a standard material for scientific equipment such as NMR spectrometers. The development of this technology by Bruker Biospin and the Karlsruhe Institute for Technology has generated new jobs and doubled production for the health, life sciences and material analytics markets.

MAGICS : from custom innovation to start-up creation

Research on retrieving sensor data to control remote handling equipment in extreme radioactive environment has led to a hardened integrated circuit design with concrete applications in the space field (ESA contract, Mars mission project…).

ASG Superconductors‘ business growth to boost local economy

As the company becomes a key player in the superconducting magnet global market, ASG Superconductors is implementing a dynamic recruitment policy, attracting new talents, and expands internationally, with contracts in the health and energy sectors in Germany and South Korea.

Space and industrial manufacturing applications to drive ROI growth

Under contract with F4E, VTT is increasing its portfolio of industrial customers, developing the skills of its team and identifying specific application opportunities for the technologies used in the ITER Divertor handling system: nuclear decommissioning, mining, metallurgy, electronics and space industry.

TEKNIKER pushes the limit of science to perform ultra-precise measurements

Within 18 months, the Spanish company was able to invent the high accuracy tool which is capable of measuring with a tolerance of 20-micron, or a measure 25 times thinner than A4 paper. A metrology solution that could be applied for ultra-precise measurements to non-nuclear energy projects such as particle accelerators, neutron sources, robots and telescopes used in aerospace industry.

ASE OPTICS creates new jobs and increase its technical capabilities in the medical and the aerospace industries

Despite the size of the company, ASE Optics secured a subcontract for the design, mockup and testing of an in-vessel viewing and metrology system in 2015. Since then, the company has quadrupled the number of employees to 8 while it has increased its technical capabilities in the medical and the aerospace industry as well as its turnover.