The ITER vacuum vessel is one of the key components of the machine, as it must provide a high-quality vacuum for the plasma to be produced and acts as a first safety containment barrier. It consists of nine sectors connected and a series of flexible support housing (FSH), around 180 per sector. In each FSH stands a threaded hole to realize the connection to the blanket modules. Like for the other components of ITER, drastic tolerances are required for these holes, and each of them must be precisely inspected and qualified.

To realize these compliance measurements rapidly and with a high accuracy, the Italian SME AXIST developed in collaboration with F4E an innovative measuring tool able to automatically inspect holes (diameter, axis perpendicularity, thread step, angle and length). This Housing Inspection Tool (HIT) is composed of a specific device designed to be centered on M130 and M150 holes and to support the automatic movement of a set of three spot laser sensors, and a dedicated software that manages the data acquisition, along with the metrological and the laser procedure.

The HIT was successfully applied during the FSH compliance phase, ensuring that every threaded hole was within the requirements. Moreover, this phase has been greatly accelerated as the HIT only needs 5 minutes to perform all measurements.

A further use of the HIT algorithm to manage laser-based surface reconstruction processes and facilitate industrial product control in the steel industry

The HIT software is a real suite which enable communication in real time with the commercial measuring software. It also includes a calibration algorithm for the reconstruction of the data in an extremely accurate way and a fast best-fit algorithm for the creation of the desired geometries.

Building on this success, AXIST further used the knowledge acquired during the HIT project and developed a new inspection system for the steel industry.

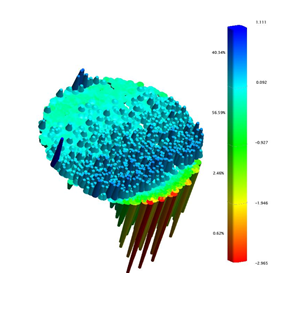

The Italian company ABS was looking for an efficient algorithm to manage the 3D reconstruction of steel profiles to detect the presence of superficial defects and control their geometrical features. The software was adapted to control two lasers moving along an axis and to reconstruct the cloud point at the same time. Calibration and best-fit algorithms were also used in the development of the new system. In the end, the new system allows ABS to carry out high accuracy controls of its production, in fewer time and without any manual intervention.

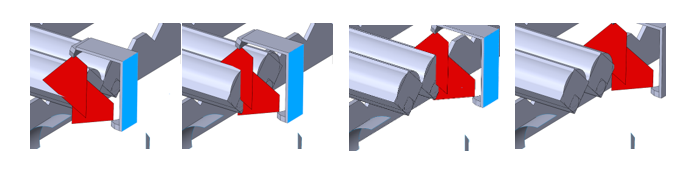

As the figures show, the principle of measurement is the same as HIT for the Vacuum Vessel: the two lasers move along an axis and acquire data, at the same time the software reconstructs

Developing new skills to address new markets: how a collaboration with F4E can boost a SME competitiveness and create value for the industry outside the ITER project

In quality control process, nowadays it’s necessary to have custom solution in order to minimize time and resources. However, it’s difficult to find integrated solution, so usually the operator must elaborate data acquired by conventional or unconventional instrument and to make a report. A great help is the use of measuring software (for example Spatial Analyzer) that permit the extrapolation of geometrical features of the measuring object, but they need the presence of a specialized operator. HIT projects contributed to this R&D challenge by increase the intrinsic accuracy of unconventionnal instruments and equipment, adjusting and adapting the solution to any geometries and replacing manual inspection by automated ones, limiting human error and fatigue.

For AXIST, the collaboration with F4E on the HIT project permits the SME to increase its know-how in kinematic calibration of multibody system, facilitating the creation of customized process to calibrate different kinematic chains. Regardless of the geometry of the part to be inspected, the HIT firmware and software are now easily customized to fit new challenges where surface or holes qualification is needed.

Working for F4E pushed AXIST’s teams to use all their expertise to create an innovative system capable of fulfilling the demanding ITER tolerances requirements. This collaboration allowed AXIST to acquire new skills in metrological procedure and laser measurement acquisition. This new expertise allowed AXIST to increase its visibility toward fusion and-non-fusion industries, starting with the steel industry. The resulting new contracts have led to a revenue increase. The first successful transfer will foster AXIST know-how and technologies dissemination in the European market.