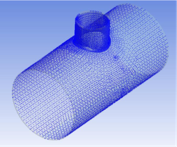

F4E, with the collaboration of the expert Professor Prinja and the Consortium Ansaldo, Mangiarotti & Walter Tosto have developed a series of Artificial Intelligence models for the processing of phased array ultrasound testing (PAUT) output data. These AI-based tools have been designed to identify weld defects through a prediction based on the PAUT data obtained. The solution provides an optimization in time and operational costs, especially in environments where large amounts of PAUT output need to be processed periodically, such as pressure vessels manufacturing.

Technology assets

- This solution reduces significantly the time required for processing PAUT output and minimizes human error.

- The AI models are trained on historic data and can be used to learn from experience and help improve Quality Control.

- The developed models have already been tested for PAUT data generated from ITER Vacuum Vessel welds that use 316LN-IG stainless steel, developed for applications that require high resistance and good weldability.

Interested in this technology?

Contact

Fusion for Energy Technology Transfer Programme

technologytransfer@f4e.europa.eu